TECHNOLOGY DATA

Plastic for Anti-Static Use

-

Summary

Plastic has a wide range of application in packing materials, building materials and vehicle’s interior part for life.

But if static is accumulated for a long time, it has harmful effects on our life.

because it has an electrical insulating properties unlike metal.

Surface inherent resistance (Ω/□) Propose Application 10^13< Electrical insulating Electrical insulating 10^13 ~ 10^12 Prevent the interference at stationary state For anti-static 10^12 ~ 10^10 Prevent the interference at dynamic state 10^9 ~ 10^6 Prevent electric accumulation, Instrument protection, Tray 10^6 ~ 10^3 Coating for Electromagnetic Shielding , Flooring for clean room Electromagnetic Shielding 10^3< Electrode, ITO Glass Electrode (ITO Glass) Take a step as follows, in order to resolve a static obstacle of plastic.

(1) Put low molecular-typed antistatic materials being spread mixed on surface of plastic.

(2) Put mixed macromolecular antistatic material with carbon, electrical filler.

(3) Spread macromolecular electrical coating liquid on surface of plastic -

Anti-Static Type

ICP Coated IDP added Method Surface

Resistivity

<10^9Ω/sq. <10^10Ω/sq. ESD STM 11.11 Friction

Charge

Voltage<100V <100V ESD ADV 11.2 Anti static Semi-permanet Permanent - Dependency

(on temp, humidity)Stable Stable - Particle

(against abrasion)None None -

General Distinction way to Plastic

-

PP

A buoyant having a density of 0.9g, It’s not melted in all solvents shade temperature but melted in toluene and rain etc.

It release blue flame having yellow color easily and also candle smell when burns continually if far from flame.

Smoke outbreak is smell but its forming parts is hard and feels like candle. it is not broken unless cut. -

PE

A buoyant material and it’s easily cut by knife. lt’s not almost melted in general solvents but melted in hot benzene or toluene.

It’s flammable highly and burnt rapidly. Charcoal is fallen and it smells a buring wax or paraffin when it burns. -

PS

It sinks to water slowly. It releases blue flame, string smell, many smoke and charcoal.

Forming products is soft and makes metallic sound when fallen on the hard surface.

It’s rarely not cut by knife and melted by carbon tetrachloride -

ABS

It’s cut flatly by knife and the cutting part has a soft end. It has anti-fragility and also stregth properties. It releases yellow flame haning a many charcoal charcoal and scid smell having a rubber one when it burns.

It smells phenol a little. -

POM(Acetal)

It has a density of 1.41g and sinks to water easily. It does not make a transparent grade owing to crystalline structure.

Natural grade is solid and white forming product. When it burns it releases light blue and pungent smell of formaldehyde,

It’s difficult to cut has smooth end.

Elctromagnetic Shielding

- Electromagnetic Interference, EMI Disturbance that affects an electrical circuit due to either electromagnetic induction or electromagnetic rediation emitted from an external source.

- EMI Shielding Protecting an electrical circuit form noise intruding from the outside of electronic equipment or no emanation of noisy out.

-

Shielding effects

Measurement Method-In general the shielding effect/SE is indicated with unit dB which is the measure of degree of the strength reduction when noisypass

through a shielding product. The degree is classified as under.

- 10~30dB : Effective a little

- 30~60dB : Effective

- 60~90dB : Effective a great

- 90dB and over : Effective the highest level

SE defines as under

SE = 20 x Log(Et/Ei), EdBElectromagnetic wave shielding mechanism

-

Reflection of electronagnetic wave

To make electromagnetic shielding to reflect the electromagnetic, the charge carrier is essential on the shielding surface.

The charge carrier will co-operate with the electromagnetic waves to take a action of electromagnetic reflection It is not always a good shielding (cause of co-operation with the electromagnetic waves to take a action of electromagnetic reflection

It is not always a good shielding (cause of co-operation with electromagnetic filed) even if has a high conductivity by the charge carrier which makes the shielding conductive. just 1 S/cm will be enough for the conductivity.

In case for metal, the reflection will be effective by the movable electron on metal. However owing to high weight, metal is coated on bulk-material, fiber and particles.

We can divide three coating methods, which are electro plating, electroless plating and vacuum deposition. But material coated by metal is weak on scratch. -

Absorption of electromagnetic waves

To absorb electromagnetic waves, it is crucial for the shielding materials to have electric or magnetic dipole characteristic.

These dipoles absorb energy by interaction with the electromagnetic field. Electric dipole exists in high dielectric constant materials such as BaTiO3 and magnetic dipole exists in high magnetic permeability materials like Fe203. The shielding effectiveness increases through the loss of energy when the electromagnetic waves pass through the shielding materials.

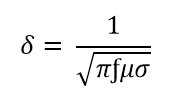

Electromagnetic waves absorption loss is a function of O.U which is multiple of electric conductivity o and magnetic permeability u.

These constant are represented as a relative values to copper, where constant of cooper is 1, and expressed as o,r and u,r

Silver, copper, gold, aluminum, etc, that have high electric conductivity are excellent electromagnetic wave shielding materials.

Super-permalloy and Mu-metal are excellent electromagnetic wave absorbing materials owing to their high magnetic permeability.

| Material | σr | μr | σrμr(absorb) | σr/μr(reflect) |

|---|---|---|---|---|

| Silver | 1.05 | 1 | 1.05 | 1.05 |

| Copper | 1 | 1 | 1 | 1 |

| Gold | 0.7 | 1 | 0.7 | 0.7 |

| Aluminum | 0.61 | 1 | 0.61 | 0.61 |

| Brass | 0.26 | 1 | 0.26 | 0.26 |

| Bronze | 0.18 | 1 | 0.18 | 0.18 |

| Tin | 0.15 | 1 | 0.15 | 0.15 |

| Lead | 0.08 | 1 | 0.08 | 0.08 |

| Nickel | 0.2 | 100 | 20 | 2x^-3 |

| Stainless Steel (430) | 0.02 | 500 | 10 | 4x^-5 |

| Mu-metal(at 1kHz) | 0.03 | 20.000 | 600 | 1.5x^-6 |

| Superpermalloy(at 1kHz) | 0.03 | 100.000 | 3.000 | 3x^-7 |

Source:JMEPG 9(3), p350, 2000

Multiple reflections: the reflection and absorption of electromagnetic shielding capabilities by adding a mechanism is the multiple reflections.

A lot of shielding materials present in the boundary of the Surface and the reflection repeat. This mechanism function on side surface, and boundary.

The following expressions, such as electrical conductivity has relationship.

Th electrical conductivity the value grows conmersely.

Depending on the value of the electrical conductivity of conductive resins for change and, depending on volume resistivity and electromiagnetic shielding efficiency of the frequency changes.

| Volume resistivity (Ω·cm) |

10^-6 | 10^-5 | 10^-4 | 10^-3 | 10^-2 | 10^0 | 10^2 | 10^4 | 10^6 | 10^6 | 10^10 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Conductive plastics for |

|

|||||||||||||||||||

| Compare materials |

Silver, copper | Iron, Conductive plastic |

Graphite | Carbon Fiber |

Germanium | Silicon | Glass | |||||||||||||

| Conductive |

|

|||||||||||||||||||

Source : http://www.jst.go.jp/pr/report/report140/

| Volume resistivity (Ω·cm) |

SE(dB) | |||

|---|---|---|---|---|

| 10MHz | 100MHz | 500MHz | 1GHz | |

| 1 | 42 | 35 | 34 | 36 |

| 10 | 31 | 22 | 17 | 15 |

| 100 | 21 | 10 | 4 | 2 |

Source : Polymer Science Technology , 12(5), 2001